5 July 2024

CFD Simulation of Biogas and Oxygen Mixture Revealed the Mystery of Biofilm Formation in Digesters

This collaboration began with a request from a team of scientists studying environmental technologies.

The task was: "We are observing something we do not understand and cannot measure experimentally." The scientists then described the challenge of biogas production from wastewater and agricultural production resources. These sludges are slowly mixed in a rotating vessel called a digester. Through an anaerobic process, biogas is produced and bubbles to the surface into the digester headspace. Unfortunately, the biogas contains even tiny amounts of hydrogen sulfide (H₂S), which is toxic and corrosive. The process of removing H₂S is called microaeration. This involves the biological oxidation of H₂S by sulfide-oxidizing bacteria (SOB). Bacteria require oxygen (O₂) to grow. Therefore, oxygen is added to the digester headspace area.

Unfortunately, although the bacteria remove H₂S, they also form a biofilm on the walls of the digester, damaging its structure. To counteract this, the scientists attempted to add replaceable circular walls (cylindrical baffles) into the digester headspace to divert the biofilm from the digester walls. Experiments showed that the digester walls were indeed protected. But, surprisingly, the walls were protected only up to the height of the cylindrical baffles. This observation was surprising, leading them to request a simulation of the process of mixing biogas with oxygen in several configurations: with an empty headspace, with replaceable circular walls submerged in the wastewater, and with cylindrical baffles raised above the sludge's surface.

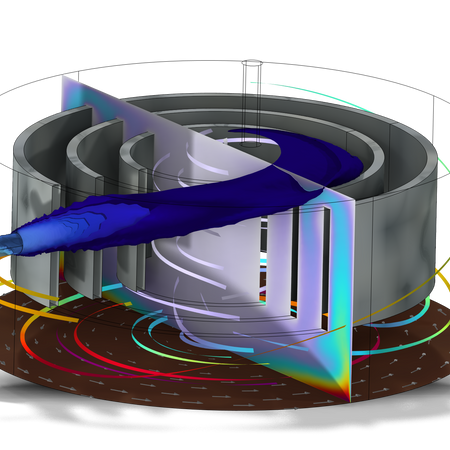

The process is continuous, so we performed a stationary study. After understanding the task, it became clear that it was unnecessary to compute with sludges below the fluid flow surface. Then, the main challenge was modeling the entry of biogas through the rotating surface of sludges. This was successfully achieved by using cylindrical coordinates on the inlet boundary. This allowed the addition of tangential velocity to the upward-moving biogas. The parabolic shape of the rotating surface was neglected after consulting with the scientists, as the rotation was slow enough. The oxygen inlet concentration was simulated as a different phase.

In the empty headspace simulation, the biogas from the sludges was carried to the walls by centrifugal force with injected oxygen together. The gas mixture was evenly distributed throughout the headspace.

When cylindrical baffles were raised, the biogas with oxygen was carried to the walls by centrifugal force. However, the velocity between the last cylinder and the wall was much higher because of a cross-section reduction. This led to shorter residence times in the area and probably insufficient time to feed bacteria. That was the mystery explanation.

Simulation results showed that the gas mixture could not be directly pushed to the walls when cylindrical baffles were immersed because the cylinders interrupted the flow pattern. The mixture flows from the center from one gap to another. The mixture's residence time between the cylinders could have caused all oxygen to be consumed.

After reviewing the results, the scientists also concluded why they measured a relatively high oxygen concentration in the outlet. The 3D visualization explained that the injected oxygen started its journey close to the outlet.

The simulation model was created using COMSOL Multiphysics with the CFD Module. Results answered scientists' questions and helped in the process of digester headspace innovation.

Project in Numbers

3.5

Approx k€

2

Days

1300000

Mesh elements

Project Gallery